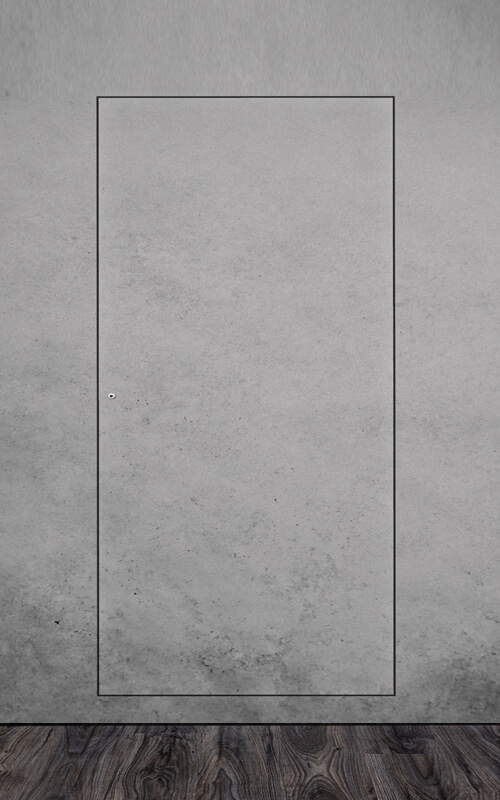

For many years, architects and designers have tried to design and build contemporary internal doorsets with a minimalist appearance by eliminating the architrave and concealing the frame. We have made it simple with our innovative solution.

A minimalist doorset is highly desirable in the contemporary interiors of today’s developments. When we set out at Selo to design the most effective concealed-frame doorset, it seemed like it should be simple. But the reality was very different. This type of slick, integrated system was challenging to achieve. In short, the dream finish was a nightmare to create.

We have seen the concealed-frame doorset approached in many ways elsewhere in the marketplace. However, existing solutions always consisted of a medley of plasterboard, timber frame and plaster beads. The majority simply look very poor and don’t work. Others work in principle and the desired effect is there, but they require a huge amount of precise and fiddly installation work on site. This is detested by the installer, who is usually on a tight deadline. If this time-consuming process is rushed, it results in a poor finish.

A key aspect of this design challenge is longevity. The finished doorset should be robust. If the finish consists of a delicate concoction of plasterboard, beads and multi finish, it deteriorates quickly. After a short period of time and a slammed door or two, the once pristine finish changes very quickly and cracks start to appear. Repairs to the surrounding plaster are then required to regain the original look. However, this isn’t easily done and the once-sleek result soon looks like a second-hand finish and is ruined.

This deterioration is to be avoided in a high-end property where quality finishes are key to the overall aesthetic appeal that prompted the buyer to invest in the development. The problem of cracks and the consequent required repair is ongoing, resulting in further costs and upset for the property owner.

After in-depth research, we discovered the solution to this nagging problem.

We identified the weakness that caused the difficulties with this type of assembly. It was the junction between the frame, the plaster bead and the actual finished plaster, or tape and jointing compound. It was clear to us that we needed to combine the frame and plaster bead. This would ensure that the junction was robust and could be fitted to the wall, while keeping that junction strong.

A timber frame was not the answer. This material didn’t offer the versatility that was needed for a modern doorset. Our challenge was that every element was distinct and separate. These needed to operate as one unit. The existing concealed doorsets were prone to split.

We needed to think out of the box and come up with a new element. We needed to overcome the division between the metal frame and the wall structure. The frame needed to mesh with the wall. The question was how to achieve this with unyielding metal.

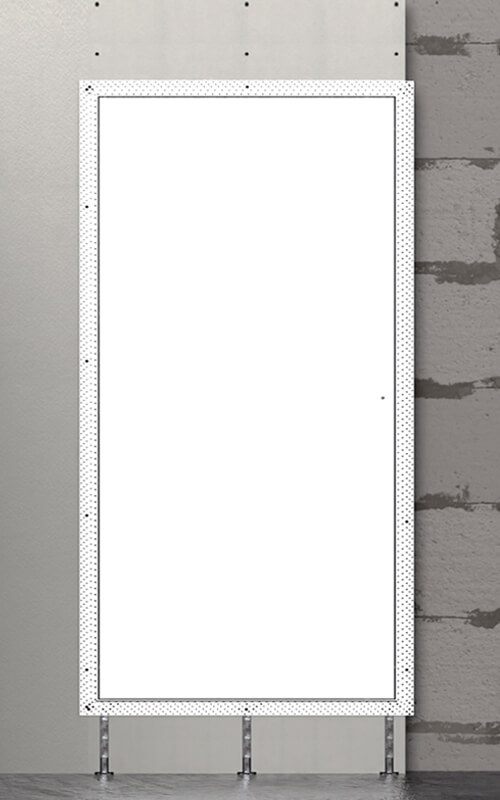

We had a Eureka moment when we designed a metal frame equipped with an integral perforated side flange. It was the ‘silver bullet’ that would eliminate the usual, deep-seated problems of a concealed frame. The perforation of the metal side flange with a network of holes maintained the structural integrity, while allowing it to connect effectively with the wall surface. This simple solution would power the success of our doorsets, which are now valued for being discreet and perfectly functional.

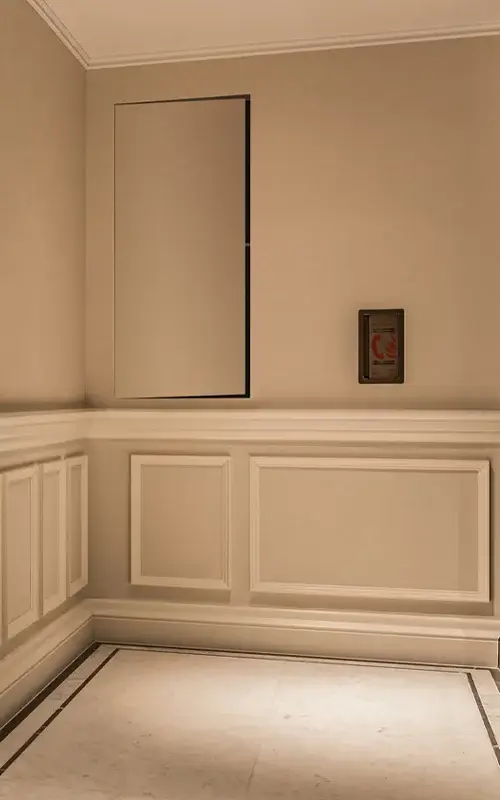

The Shard hadn’t been built at the time we developed the unique concealed doorsets. Little did we know that they would be selected for this and other prestigious properties along The Thames and top developments throughout London and further afield.

We made sure that installation would be simple and effective. Once the frame is fixed via the perforated flange into the wall, it forms an exceptionally strong structure that forms part of the wall. This can then be finished over, up to the edge of the frame, with the finishing compound (be it skim or drywall tape and jointing compound), which provides a sleek, seamless finish.

Why doesn’t the surrounding wall surface crack? The simple reason is that once the frame is fixed, it becomes an integral part of the wall. The wall structure soaks up the jarring or any other movement caused by the door shutting. If this solution isn’t in place, cracks develop when the frame and the plaster move in different directions, or when the frame moves, but not the plaster. When the whole wall structure soaks up any impact, this problem is avoided.

That’s how we like things at Selo. Simple solutions.

Watch this space. Next month, we will outline the various scenarios where concealed doorsets are required to achieve a sleek, seamless finish.