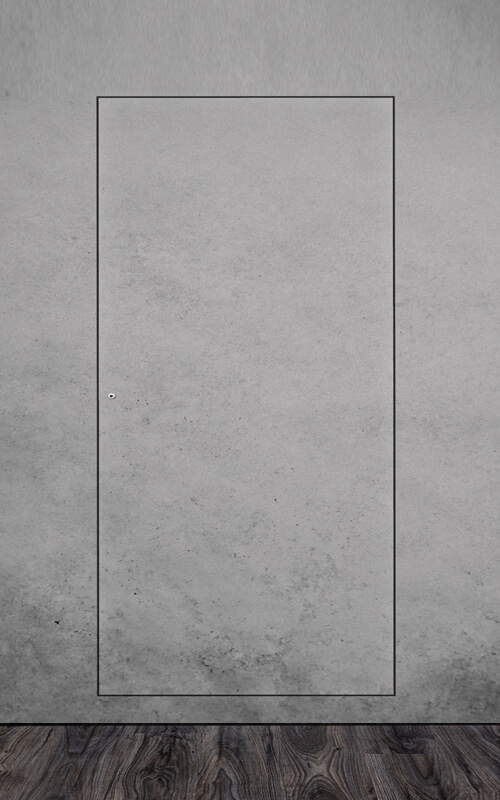

Introducing Tempus Lift Shaft, the first fully compliant and reusable temporary lift shaft. The reason for this product is to provide temporary fire protection and smoke protection to lift shaft openings, during the construction phase. Tempus Temporary Lift Shaft was bought to the market to be (JCOP) compliant and as there is no other product on temporary lift shaft on the market that is fire rated, smoke rated as well as load and impact tested.

Read more to find out why Tempus Lift Shaft is the first fully compliant temporary lift shaft solution as well as learn more about the features and JCOP.

FD60 fire rated

Tempus Temporary Lift Shaft was designed to maintain compliance throughout multiple construction projects in line with JCOP. We have fire tested to EN1634 to provide 60-minute (FD60) fire resistance in both directions.

Smoke rated

Tempus Lift Shaft is smoke sealed as standard to provide fire and smoke protection in line with JCOP. As part of our asset management service, we take care of everything to provide worry-free compliance. This includes cleaning, change of seals, testing and adjustments, storage, ready for your next construction.

Load and impact tested

Designed for maximum durability and to be used on multiple construction sites, Tempus Lift Shaft has also been load and impact tested to BS EN 13374:2013+A1:2018 and BS 5234-2:1992 Annex E.

Change in legislation - JCOP

The joint code of practice on the protection from fire of construction sites and buildings undergoing renovation – tenth edition incorporating amendments 1 and 2. Amendment 2 was published in May 2025.

First published in 1992, the JCOP initially set out to prevent fires on construction sites but has since been revised address new risks from modern materials and construction methods as well as long-standing risks. The document outlines the need for fire and smoke protection in lobby areas and smoke shafts during the construction phase to protect those working in the building during its construction.

Section 9.1 states “The client, designers or principal designer should ensure, so far as reasonably practical, that the project is designed and planned in conjunction with the contractor and their programming of the works to achieve the early installation and operation of:

(b) fire compartments within the building under construction, including the installation of fire doors and the completion of fire-stopping, with special attention given to lift shafts, stairwells, service ducts and voids which offer a passageway to heat and smoke;”

And section 23.5 “Where reasonably practicable, the building should be horizontally fire compartmented at intervals not exceeding five floors, to prevent the upward (or downward) spread of smoke and flames. This should be done at the earliest practical opportunity after construction of each of the relevant floors, using temporary fire-stopping materials having no less than 60-minutes’ fire resistance (integrity and insulation), until the permanent fire-stopping arrangements can be put in place. All holes, shafts and openings should be closed off, including service risers, lift shafts and stairwells. Temporary fire-stopping can be removed to allow construction operations in the area to be carried out, but must be replaced whenever work stops. It should not be left out of place outside site working hours, i.e. at night and at weekends.”

24.5 “The building should be compartmented and fire stopped at the earliest stage possible. This should include party walls, stairwells, service risers, lift shafts, roof voids and other fire-rated sub-compartments throughout the building. Wherever possible this compartmentation should take the form of the final, permanent fire-resisting doors, panels and fire-stopping.”

Features

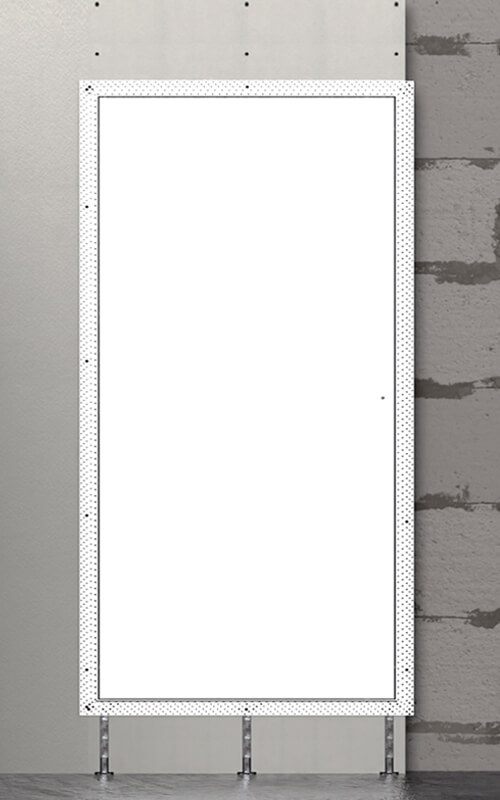

Lift off hinges which makes the doorset very quick and easy to assemble and disassemble when transferring the reusable temporary lift shaft the next project.

Oversized and face fixed which allows the temporary lift shaft to be used in different opening sizes. This allows the temporary lift shift to be reused on multiple projects.

Three point lock system to enable the temporary lift shat to be locked from the outside with a triangular key operation. The doorset can be opened from the inside without a key, providing a safe exit in case anyone was shut inside.

Integral safety gate provides protection against fall arrest once the door has been opened. The door opens to 180° for clear access.

Asset management to give our customers worry-free compliance. Once your project has finished, we will collect the temporary lift shaft from site and store at Selo House. We will also clean, change the seals, conduct any required testing and make any necessary adjustments ready for your next project. We take care of everything from start to finish including delivery and collection.

Reusable to be used on multiple projects

Tempus Temporary Lift Shaft has been made from heavy-duty steel and is designed to be hardwearing to be used on multiple construction sites. Our asset management system removes the hassle of storing the lift shaft in between projects and we will also handle any testing or adjustments required to maintain compliance on your site.

Bok a call to find out more about Tempus Temporary Lift Shaft

If you would like to find out more about Tempus Lift Shaft or how to remain compliant with JCOP please contact us today.