Fire Door Safety Week is a UK wide campaign to raise the awareness of fire safety and how fire safe doors can play a vital role in saving lives.

At Selo, we exist to simplify bespoke and complex building methods, and creating innovative, aesthetic fire compliant solutions is at the heart of what we do. But we also aim to educate the market, to enable safe and compliant fire solutions.

We sent out a survey to gauge how much you know about fire compliance best practice, and in this article, we answer some key questions to achieving a fire safe door solution.

What are the key considerations when testing and specifying fire doorsets?

It’s important to understand the application the doorset has been tested for. For example, has the doorset been tested for integrity only, insulation, smoke, or all three? Fire compliance requires a holistic view of your project and the different fire requirements.

It is also crucial to know that your door has been tested to the relevant standards and suitable wall construction to ensure the wall as a system is/remains compliant.

What test standard (BS476 series or EN1634 series) the door has been tested to. Currently, both are acceptable standards in the UK although the BS476 standard is being withdrawn from building regulations as acceptable in a move away from national standards to the maintained European standards and change to more of a rule based, system of approval.

What key things would you look for on a fire doorset to check its compliance?

- Certification – fire doors should be rated FD30 (BS476-22) as a minimum. EN classifications are better, as national standards are outdated and being removed from building regulations for fire resistance and reaction to fire.

- Duration the door has been tested to and the requirement for the wall and building as a system.

- Ironmongery – ensure the ironmongery used on the door is as tested and approved for the doorset. Also, that it has been correctly fitted and only the approved intumescent has been used where it is required to be fitted.

- Gaps – on the side of the door should be 3mm around the door or as specified in the test evidence if greater.

- Where possible check the fire door was installed with the correct fire stopping detail into the wall and is approved for that wall system.

Do you know why it is important to maintain a fire doorset?

Fire doors must be regularly inspected and maintained to ensure they are still compliant and keep people safe. Damage and wear and tear during use may affect the fire doors performance including its ability to self-close. When procuring a fire door, look for solutions that have been rigorously tested and in their intended wall installation.

Do you know the difference between FD30 and EI30 fire rated doorsets?

According to our survey, 37% of people who work within the construction industry do not know the difference between FD and EI rated fire doors. Although, currently, doors can be compliant by passing, tests with either standard, it is important to know the difference as they have different criteria and the rules on compliance is changing.

FD fire ratings are based on Fire resistance testing to BS476-22 and state the duration a doorset or assembly can resist a fire. The ratings are formatted FD30, FD60 or FD120 to indicate how many minutes a door meets the test requirements for integrity and where relevant insulation criteria.

The EI rating, standing for ‘Integrity (E) and Insulation (I)’, also indicates how many minutes a doorset or assembly meets the test requirements for integrity and insulation criteria when tested to EN1634-1 and classified to EN13501-2. These European standards for testing and classification are the only method allowed in the new revision of approved Document B.

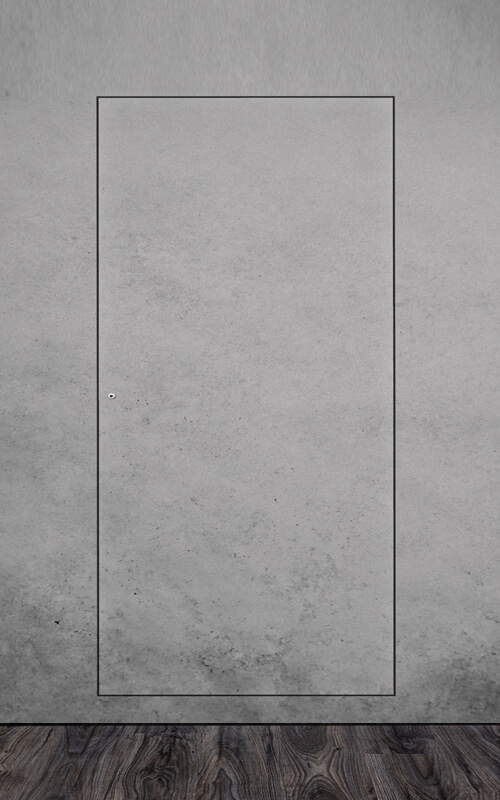

Does my fire doorset need to have been tested with my wall construction?

According to our survey, 53% of users either were unsure, or thought that a fire doorset did not have to be tested within the wall construction. The answer is yes, the fire doors must be tested within the wall construction you plan to fit the door into or currently can be competently assessed normally by a certification approval body. The wall and door should be treated as a system so where a wall is not a standard construction as defined in EN1363-1 the doorset should be tested in the specific associated wall construction.

What dimension is the fire stopping gap around a fire doorset?

According to our survey, 63% of people in construction did not know the answer to what dimension a fire stopping gap around a fire doorset should be. There is no specific dimension and fire stopping gap around a fire doorset should be. However, the manufacturers documentation should specify clearly the maximum and minimum gaps and method of fire stopping the gap between door frame and wall. The installation must match this detail. Fire stopping protection, such as Quench, can applied on-site, saving your contractors time and mitigating risk and non-compliance.

Can I put any ironmongery on a fire doorset?

Based on the results of our survey, 23% of users in construction thought you could fit any ironmongery to a fire doorset and the fire door would remain compliant. Fire doors can have fire rated ironmongery that was on the door during the fire test and meet the same fire classification or alternate ironmongery which has been suitably and competently assessed by a certification approval body.

What is the biggest cause of death from fires? (Burns, Heat, Smoke)

Our survey indicated that 100% of users who took part knew that smoke was biggest cause of fire related deaths, which is correct. Smoke inhalation is the common cause of death during a fire, Fire doors should be specified to have smoke resistance at ambient temperature where required. Additionally lobby/corridor smoke control dampers as part of a smoke extraction system should be considered during the procurement stage of your project enduring a compliant smoke extraction system is in place where required to aid safe escape and evacuation.

When do you go by the wall certificate and when do you go by the door certificate?

Both the wall and the doorset certification and application detail must be checked by a competent person to ensure that not only they meet the requirements in isolation but also when integrated as a system.

Fire foam has a performance certificate. Can I use that on any fire door?

No, polyurethane foams should only be used if they have specific testing and approval with the doorset and wall combination being used.

Do the European standards set a limit on fitting tolerances?

No, the fitment and fire stopping should be as detailed by the certification and manufacturers instructions. This should be based on direct fire test evidence to EN1634-1

Does every single handle need to be fire tested with every single door?

Not necessarily, as they can be assessed by a certification approval body. However, we would recommend that all ironmongery is tested with the door, or certified based on test evidence and using the EN 15269 rules for extended application of test results for fire doors.

How did you score? If you are unsure about any of these questions, contact us today to make sure your compliant!

Achieving a compliant fire doorset solution can be difficult and we understand the challenges of balancing impeccable fire compliance with unrivalled aesthetics, which is why we offer detailed project support to reduce risk on your site. If you have any questions, please contact us today.