Understanding the different wall types is vital for architects, main contractors, sub-contractors and developers to ensure a compliant door and wall system. Just because a doorset has been fire tested in one wall construction, it does not necessarily mean it will meet the same performance standards in another wall type. You must check the test report to make sure the door can perform to the required standard in the wall construction you need. Because when the door fails, the wall fails and when the wall fails, the door fails.

We offer detailed training for doors and walls as a system in our Getting It Right CPD. If you are an architect looking to upskill your team, or understand the latest changes in legislation, we highly recommend you booking our CPD.

Read below to find out more about the different wall constructions and some examples.

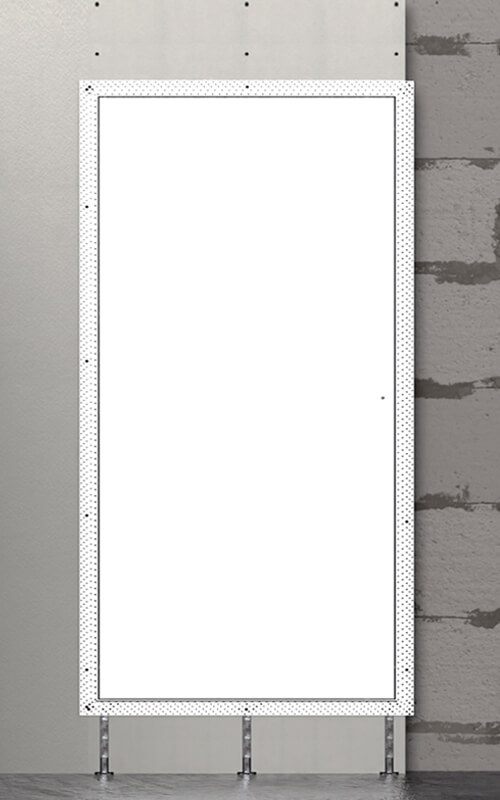

Standard Flexible

The EN 1634 definition of flexible walls refers to wall constructions that are not rigid masonry but typically consist of lightweight, framed systems such as timber or metal stud partitions. These walls are characterised by the use of independent panels on both room faces, a cavity (often filled with absorbent material like mineral wool), and linings of plasterboard with sealed joints. Flexible walls are designed to provide fire resistance and sound insulation, and their junctions with other building elements (such as ceilings, floors, and external walls) should be sealed with flexible closers or sealant to prevent air and sound transmission. The cavity between the wall linings should be a minimum of 50mm, and each plasterboard sheet should have a minimum mass per unit area of 10kg/m².

Standard flexible wall types are commonly found in developments as they are often a quicker way of constructing walls.

Some common examples of standard flexible wall types are plasterboard steel stud partitions and plasterboard timber stud partitions.

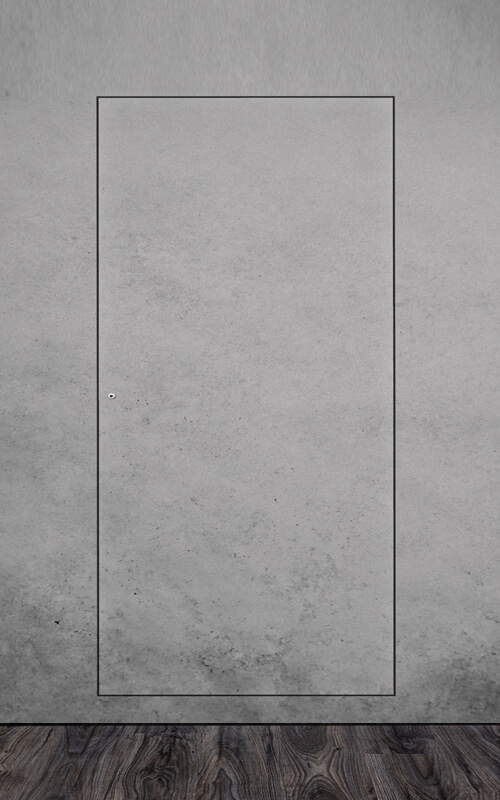

Standard Rigid

Standard rigid walls are a solid wall construction, which consists of a single continuous layer of material, such as masonry, concrete or some variations of high-density plasterboard.

Standard rigid construction is used when a robust, solid wall type is required and flexibility due to environmental changes is not required. An example of where standard rigid construction would be used are loadbearing walls or a basement construction.

Some examples of standard rigid wall types are blockwork walls and concrete walls.

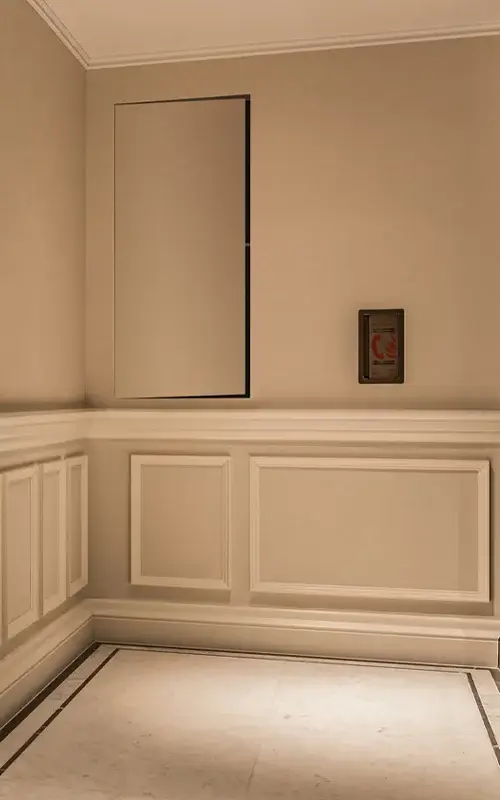

Associated Wall Construction

Associated construction is also known as non-standard. One of the most common types of associated construction we come across is risers and shaft walls but also acoustic panels and pre-cast concrete.

Achieving a compliant system using associated wall construction can be challenging, which is why we invented Nulfire.

Nulfire

One of the most common types of associated construction is when you have a rigid wall (blockwork, concreate or brick) that is finished on the front with some plasterboard through gypliner or cement.

One of the common issues we see with this system is customers like the door to be flush with the plasterboard. When this happens, you invalidate the fire integrity and performance certification, as you are pulling the door out of the fire line and into line with the aesthetic system, which effectively breaks the fire barrier.

To combat this for our Quadra+ riser doors, we invented Nulfire, which allows you to fit a sleeve system in the reveal to provide 2 hours fire protection with the Quadra+ system sitting in ‘projection’ from the fire wall which maintaining its integrity and performance, and then finished in with the aesthetic finish, concealing the frame as standard.

How Do You Know What Wall Type and Doorset Will Work Together?

To ensure your door and wall will provide a compliant system, we strongly advise checking the Field of Application (FOA) report prior to specifying the wall system to ensure that the entire system is compliant. The FOA will tell you what standard the doorset was tested to and for how long, as well as the wall type the doorset has been tested in. When specifying a door for your project, it is important to consider the entire building as a system. We also recommend reading the FIS Walls as a System guide, which our Technical Director contributed to, as a best practice guide.

Conclusion

If you have any questions about compliance on your project, or you want to upskill your team to understand doors and walls as a system, then get in touch today.